Motion Picture of 890 Nano-seconds Dynamics in Nano-particles and Polymers Captured by EuXFEL ~High-Precision Tire Rubber Degradation Evaluation~

- Headline

- Press Release

Points

- Simultaneous observation of carbon particles and polymer (polybutadiene) in tire rubber at the world's fastest time resolution of 890 nanoseconds using the European XFEL.

- The motion of each component of the composite material was measured with high precision on an atomic scale, and it demonstrates that the dynamics can change when the bonding state has different interface.

- Diffracted X-ray blinking (DXB) method can estimate the dynamics of each component in composite materials, and has potential to evaluate extremely diverse material systems which contains nanoparticles.

A research group has successfully measured the movement of carbon particles, one of the fillers used in tire rubber, and polymers with a time resolution of 890 nanoseconds, the fastest in the world, without labeling the tire rubber sample. The measurement was made using the European X-ray Free Electron Laser (European XFEL) in Hamburg, Germany. In composite material systems such as tire rubber, it is important to understand the movement of fine particles and polymers especially near the interface between different components to evaluate tire performance. In this study, this research group succeeded to measure atom-sized molecular motions at nanoseconds order. This new measurement technology will enhance the diagnostics of rubber degradation and a more durability can be expected in future.

Tire rubber, which is widely used in a variety of industries and in our daily lives, requires ever higher functionality, in particular, the grip performance and wear resistance. The structural characteristics at the molecular level, the dispersibility of fine particles in composite materials, and the interaction between the components and the base polymer (polybutadiene) are main parameters of those performances. Therefore, understanding molecular motion with nanoseconds time resolution is key to understand the relationship between structure and function.

Conventional techniques have studied the dynamic of fine particles and polymers by relying on averaged X-ray data, rendering a comprehensive component, it is not practical method for tire rubber like materials.

In 2018, Professor Sasaki and his colleagues proposed the world's first Diffracted X-ray Blinking (DXB, Fig. 1) method using monochromatic X-rays, and succeeded in capturing the internal motion of a single biomolecules. The DXB method works well not only for biomolecules, but also for molecules in tire rubber systems, which exhibit complex motions due to the complex interactions of inorganic and organic materials.

In this study, we focused on carbon black (50-80 nanometers in diameter) and polymer (polybutadiene) inside tire rubber, the main components of tire rubber, and used the DXB method to observe the movement of each component and the interaction between them with a time resolution of 890 ns, the fastest in the world. As shown in Fig. 2, time-resolved X-ray diffraction measurements were performed on two samples with different rubber compounding states. From these diffraction images, diffraction rings of carbon and X-ray halos from polymers could be identified. Next, an auto-correlation function (ACF) was performed on these diffraction regions to extract attenuation coefficients related to the motion of the fine particles and polymer structure (Fig. 3).

As a result, for the first time in the world, we succeeded in simultaneously detecting changes in the motion of each molecule related to the interaction between carbon and polymer. The attenuation coefficients obtained from the simultaneous measurements from these complex components indicate that the motion of the particulate and polymeric structures changes significantly between carbon and polymer, which is attributed to differences in the constraining environment and friction conditions at the molecular interface of each sample. It was demonstrated that the motion of each component is different near the interface between dissimilar components.

Future Prospect

One of the important phenomena in the degradation process of tire rubber is considered to be this measured change in the interface between dissimilar components. This high-speed DXB measurement has confirmed the specific kinetic properties of the molecular structures that make up the material, and the fact that the kinetic properties change in the environment around the molecules. In the future, these data will enable us to provide guidelines for more rational and highly durable material design.

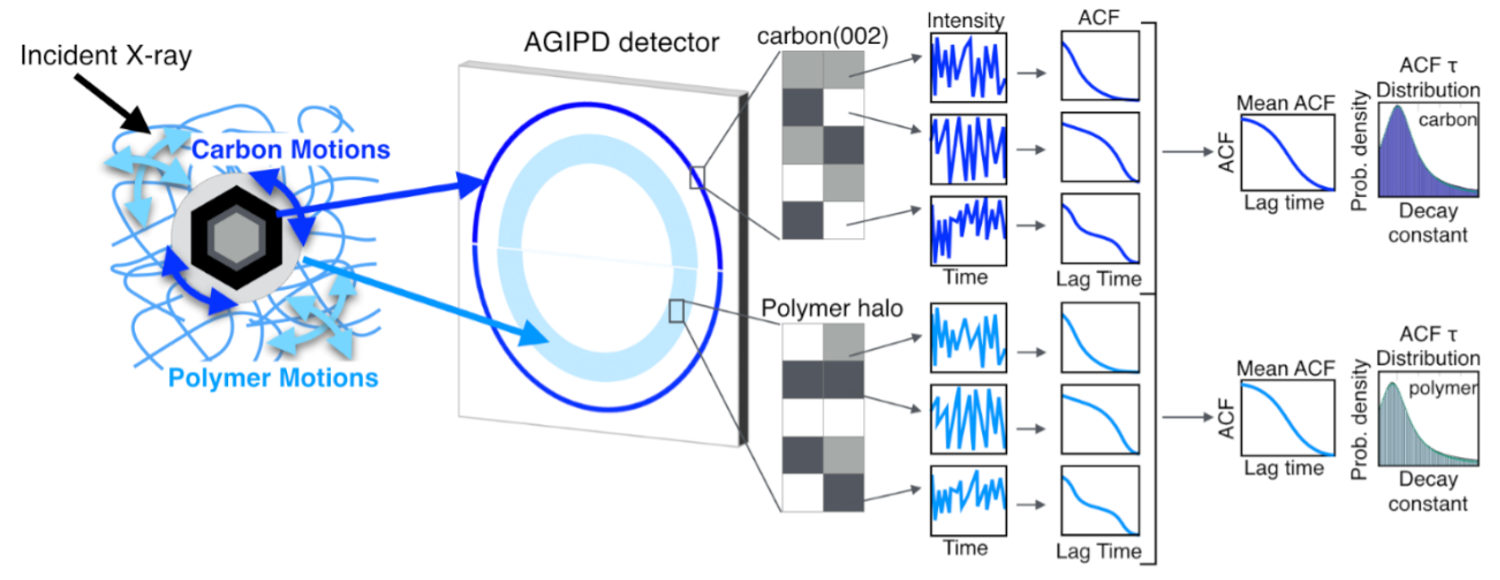

Fig.1:

Schematic illustration of DXB measurement and analysis. X-ray scattering from the carbon black (CB) and polybutadiene (PB) in L3026C and L3026F was detected on the AGIPD detector. The time-resolved intensity of single pixels on the Debye-Scherrer ring of the CB (002) plane and PB scattering were analyzed by the two-time autocorrelation function (ACF) with the lag time. Based on the results of all pixel analyses, the mean ACF and probability density of the ACF decay constants could be obtained.

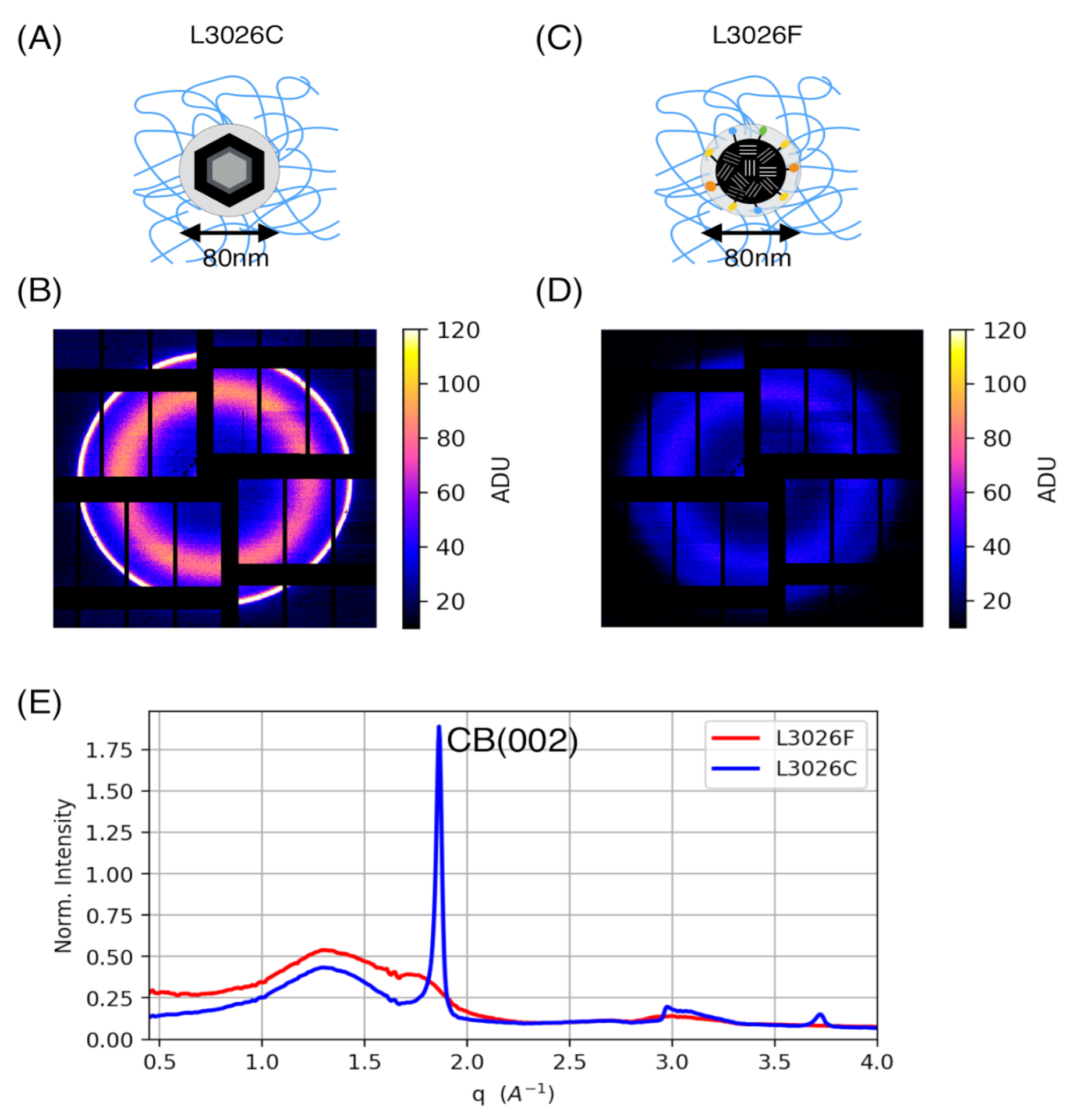

Fig.2:

The structure of rubber samples L3026C and L3026F. (A) Schematic illustration of L3026C. Tire rubber containing graphitized CB, with little interaction between the CB and the PB. (B) XRD image of L3026C. (C) Schematic illustration of L3026F. Tire rubber containing non-graphitized CB. The CB surface and PB are strongly bonded and largely interact. (D) XRD image of L3026F. (E) The azimuthal integration of the X-ray diffraction patterns.

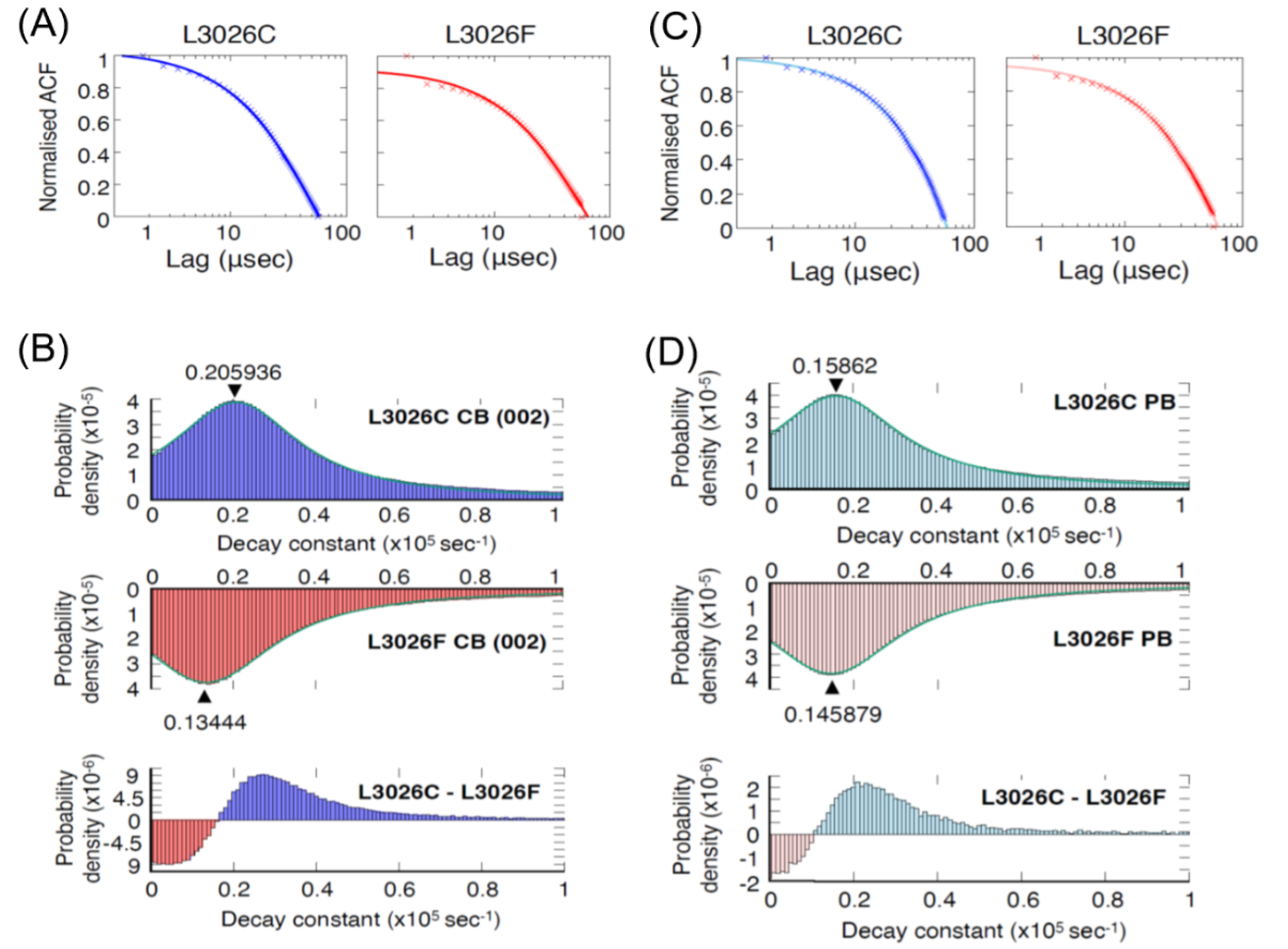

Fig.3:

(A) Normalized ACF curves for CB in L3026C and L3026F. (B) The probability distributions of the ACF decay constants for CB. The histogram on the bottom shows the subtracted distribution of ACF decay constants in CB between L3026C and L3026F. (C) Normalized ACF curves for PB in L3026C and L3026F. (D) The probability distributions of the ACF decay constants for PB. The histogram on the bottom shows the subtracted distribution of ACF decay constants in PB between L3026C and L3026F.

Reference

Applied Physics Letters (APL)Vol 123, issue 10

Direct observation of 890 ns dynamics of carbon black and polybutadiene in rubber materials using diffracted X-ray blinking

〈DOI〉 http:// doi:10.1063/5.0157359

〈URL〉 https://pubs.aip.org/aip/apl

Masahiro Kuramochi, Henry J. Kirkwood, Jayanath C. P. Koliyadu, Romain Letrun, Raphael de Wijn, Chan Kim, Tomomi Masui, Kazuhiro Mio, Tatsuya Arai, Hiroshi Sekiguchi, Hiroyuki Kishimoto, Adrian P. Mancuso, Tokushi Sato and Yuji C. Sasaki.