SUPER STRONG MAGNETIC FIELD SCIENCE

ATSUHIKO MIYATA LAB.

INTRODUCTION OF LABORATORY

To improve the performance of today’s electron devices dramatically, it is essential to incorporate new device materials with higher functionality. In the electron device operations, the carrier density change in semiconductors occurs in the near-interface region within several or tens of nanometers of the interface between the semiconductor and the insulating layer. Therefore, in order to fully utilize new device materials, it is essential to control the atomic arrangement and physical properties in this nano-region near the interface, by designing appropriate fabrication processes based on the deep understanding of the properties of those materials. For example, it is contributing to an energy-saving society to signicantly improve the efciency of power devices for electric power conversion, by fully utilizing wide-gap semiconductors instead of Si as the new device material. The materials showing superior dielectric properties such as ferroelectricity in nanometer-thick lms, are expected to be applied to new non-volatile memory technology that will support the next-generation computing.

ワイドギャップ半導体SiCのMOSFET反転層移動度のアニール処理による向上効果

ワイドギャップ半導体SiCとゲート絶縁膜SiO2の界面と、赤外分光による構造解析

MESSAGE

WHAT IS THE MOST MEANINGFUL STUDY TO DEVELOP THE TECHNOLOGIES FOR THE FUTURE SOCIETY? THAT WAS THE REASON WHY I STARTED TO LEARN MATERIALS SCIENCE. IN THE WORLD OF ELECTRON DEVICES, “THINGS WE HOPE TO DO” ARE CHANGING TO “THINGS WE CAN DO” EVERY DAY.

I majored in chemical engineering because learning chemistry seemed necessary to understand the technology for the benet of our society, such as the technologies for environmental conservation and efcient usage of energy. After graduation, I started to work with a professor leading the cutting-edge research on electron devices with in-depth knowledge of physics. While I kept struggling to pursue his many creative ideas, I nally found my way to come to where I am today. Today materials science provides one of the keys for develop-ing advanced electron devices. In this research eld, specialists in materials science are not the majority, so I always feel I am responsible for the role to clarify the technological issues in device physics from a perspective of materials science. In those researches, we cannot nd a solution without repeating trials to test our various ideas over and over again. That is how future technology develops. We should enjoy such struggling to keep moving the technology forward.

keyword

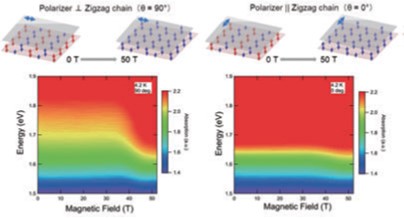

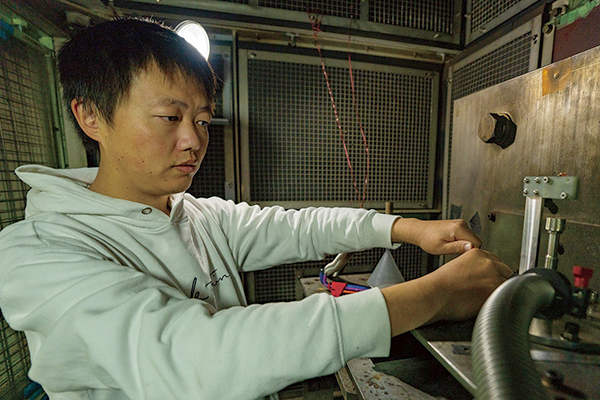

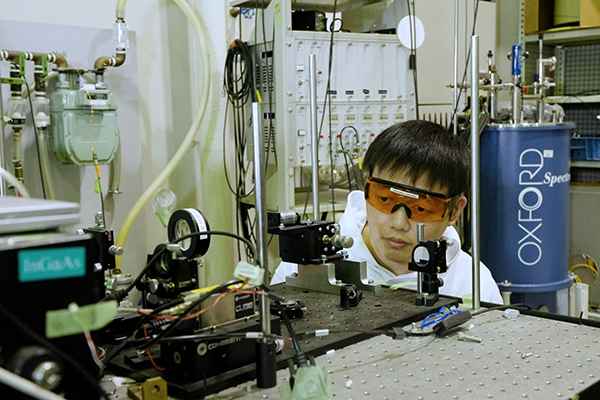

100 Tesla Science / Pulsed Magnet Development

PROFILE : Associate Professor Atsuhiko Miyata

2012 Doctor of Engineering, University of Tokyo

2012-2014 Postdoctoral researcher, Institute for Solid State Physics, University of Tokyo

2014-2019 Postdoctoral researcher, Laboratoire National des Champs Magnetiques Intenses, France

2019-2023 Postdoctoral researcher, Hochfeld-Magnetlabor Dresden, Helmholtz Zentrum Dresden Rossendorf, Germany

2023 Associate Professor, Institute for Solid State Physics, University of Tokyo

SOLID STATE PHYSICS AND CHEMISTRY

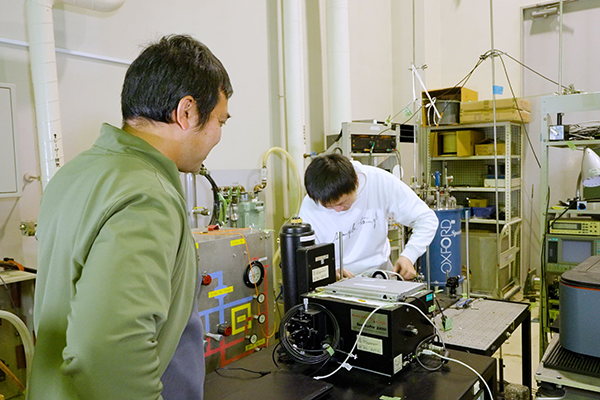

This is a new laboratory that aims to explore and elucidate new quantum physical phenomena.

Atsuhiko Miyata Lab.,

Department Of Advanced Materials Science,

Graduate School of Frontier Sciences,

The University of Tokyo

Kashiwanoha 5-1-5,

Kashiwa,Chiba 277-8561, Japan

+81-4-7136-5531

a-miyata@issp.u-tokyo.ac.jp

The Goal of Applied Physics

The goal of Applied Physics is to develop a stage = “new material” that can manipulate undeveloped degrees of freedom, to explore unknown phenomena created from that stage and to bring out excellent functions, and to bring out its excellent functions. The purpose is to contribute to the development of human society by elucidating the mechanisms and developing application fields for these phenomena and functions.

AMS (Advanced Materials Science)

Department Office

AMS (Advanced Materials Science),

Graduate School of Frontier Sciences,

The University of Tokyo

Kashiwanoha 5-1-5, Kashiwa, Chiba 277-8561, Japan

Email : ams-office(at)ams.k.u-tokyo.ac.jp

Please change (at) to @.